Samson Technologies

Octodowel

Octodowel

Couldn't load pickup availability

A load plate connector for construction joints in concrete slabs. The Octodowel system provides precision installation and simplified accuracy checks.

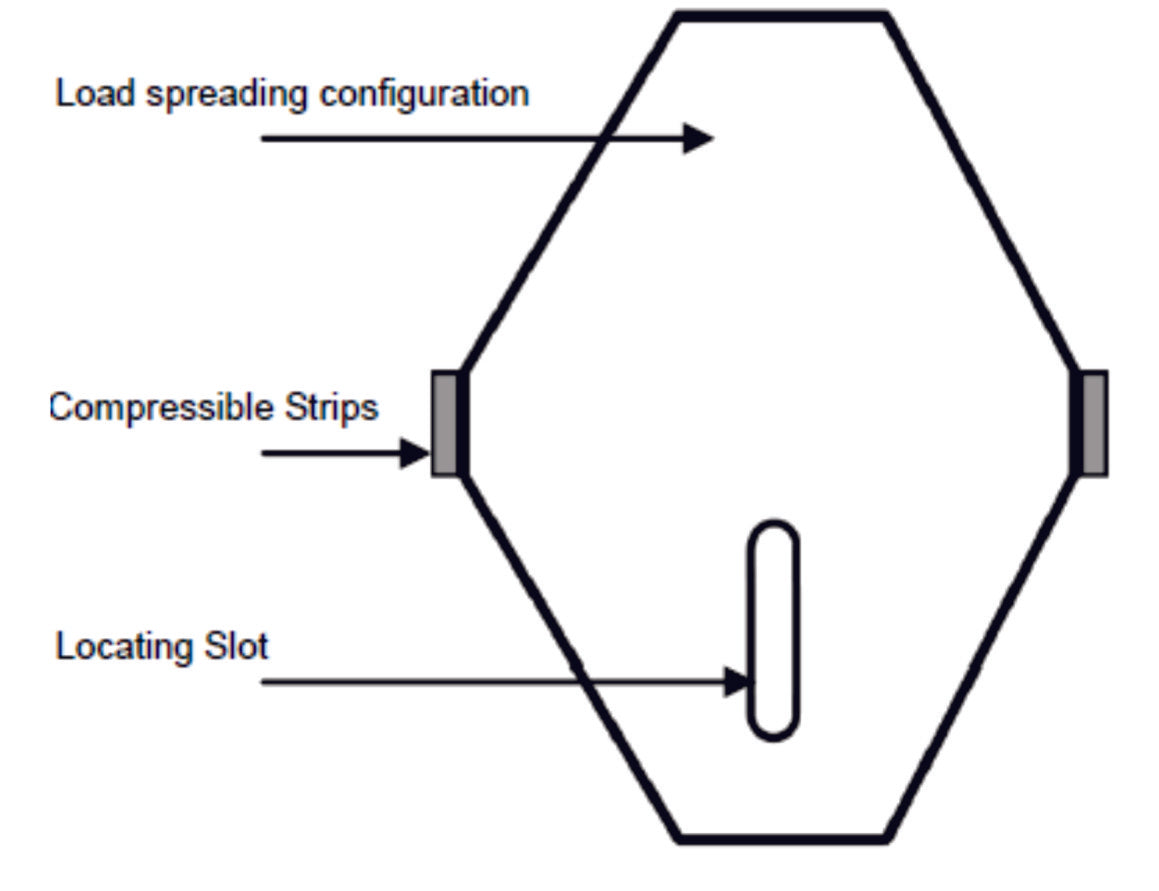

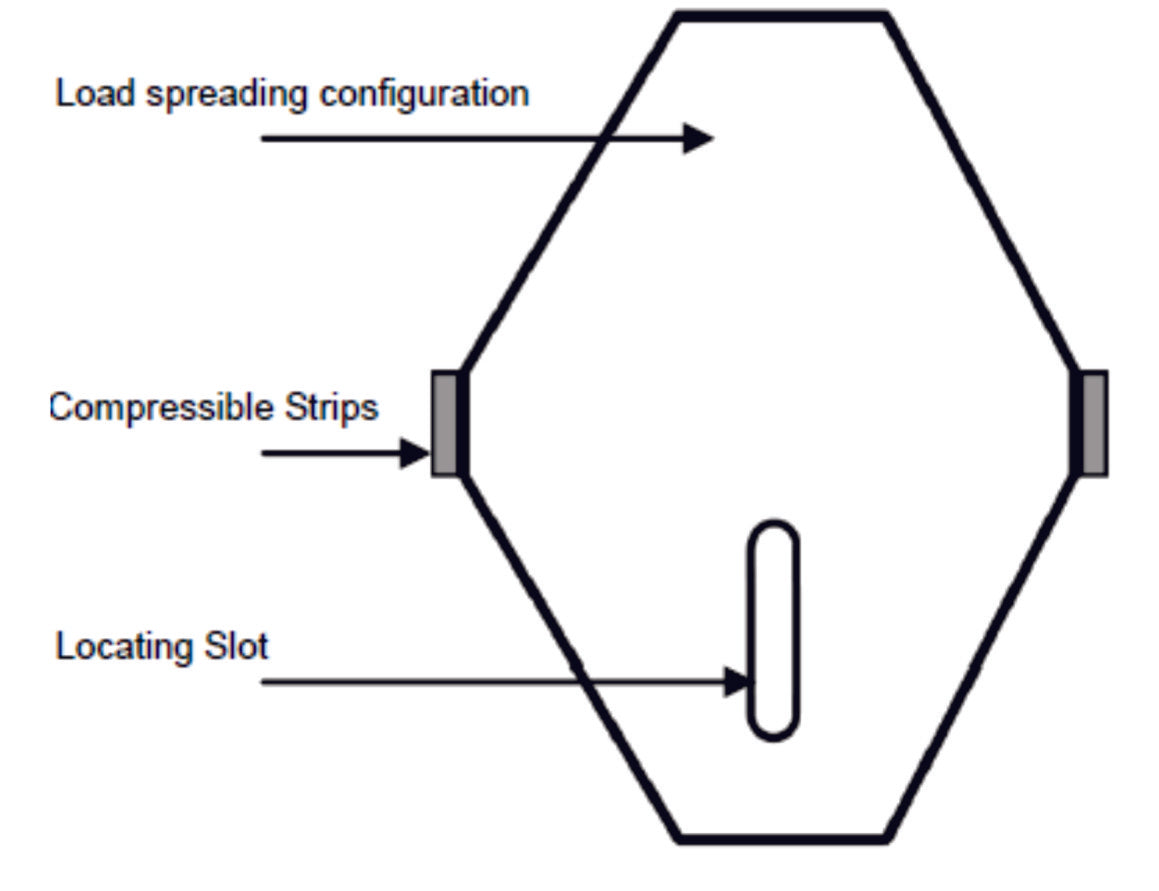

The Samson Octodowel is a patented, registered design 5mm thick commercial steel plate, cut to the profile pictured included as an image

Application:

The Octodowel installed in the Samson method, prevents differential elevations developing at construction joints in juxtaposed concrete slabs. ACI Committee 302, no longer recommends the use of formed interlock at construction joints and plate dowels are considered the most effective method of connecting concrete slabs. Samson has identified five critical factors for the construction of failure free construction joints.

The compressible strips accommodate lateral shrinkage stresses and therefore Octodowel may be installed in both directions of construction joints.

The Octodowel is the most effective and low cost method of employing plate dowel

concepts and when installed utilising the Samson techniques for failure free construction joints contributes significantly to durable concrete floor installation.

Octodowel is a component of the Samson “OmniTech” system for fine quality, durable concrete floors.

Spacing:

Recommended spacing as per the ACI Committee 302.1R-13 report, Table 3.1

Slab depth Spacing (centre to centre)

Less than 200mm 450mm

More than 200mm 500mm

Installation Procedure:

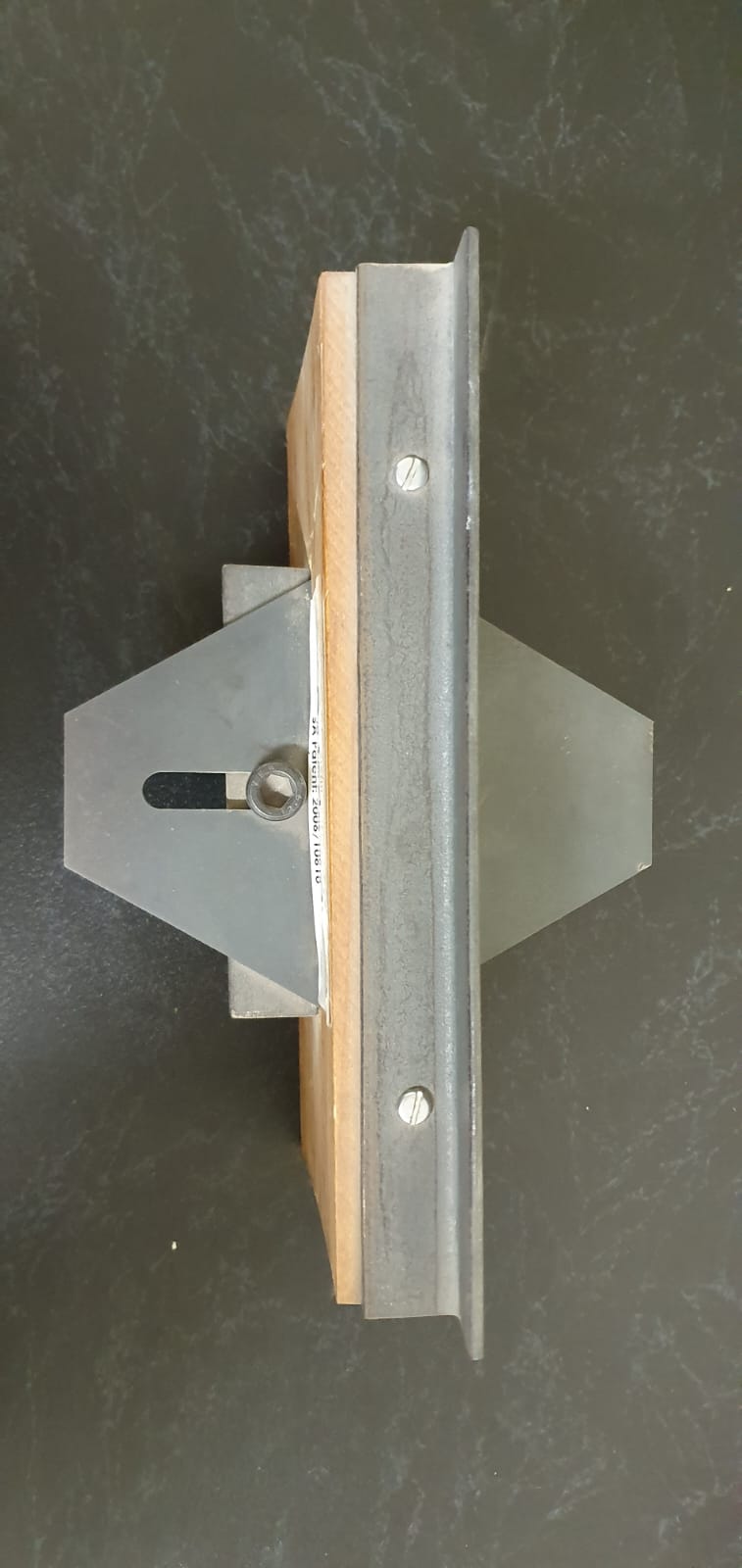

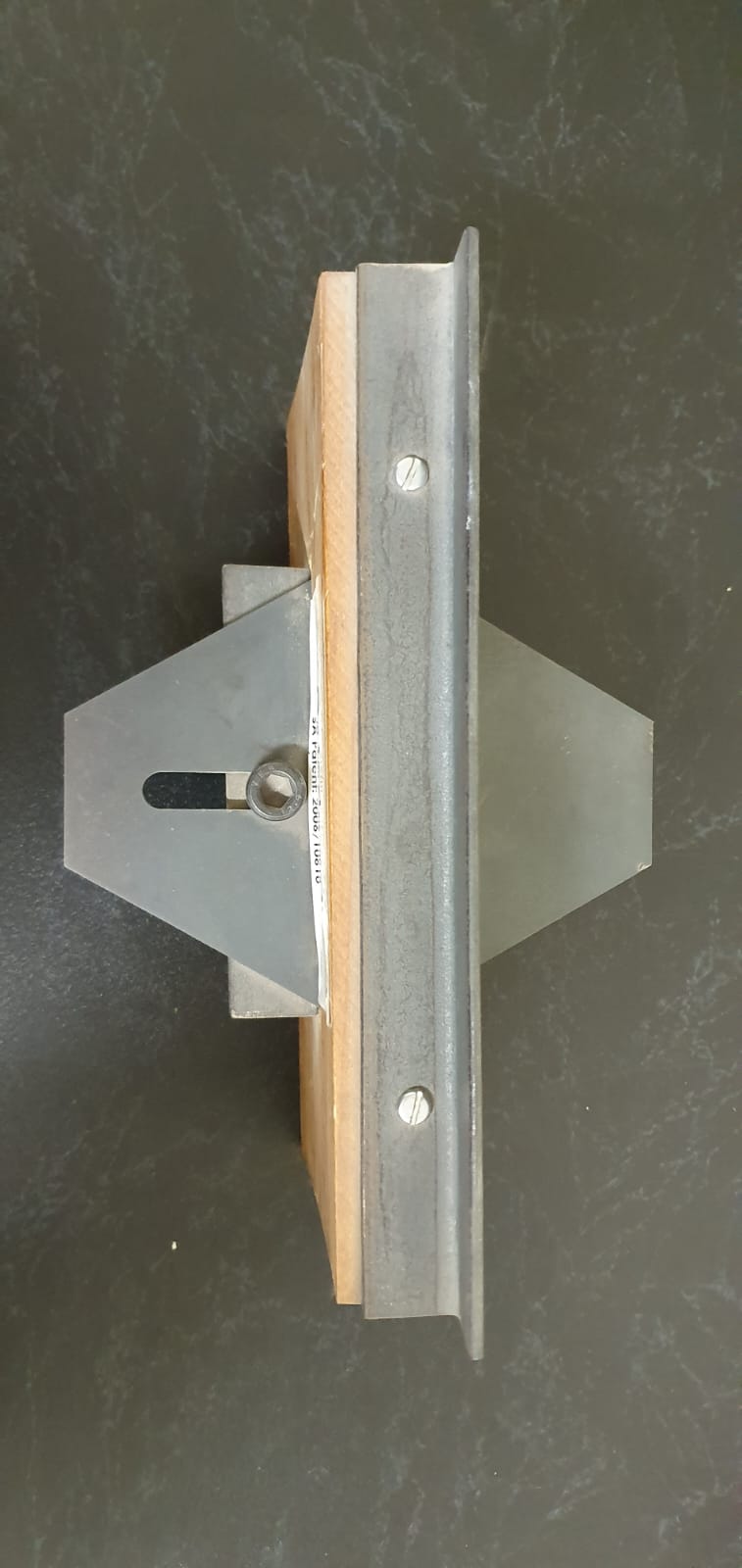

The Octodowel is inserted into a 6mm x 126mm slot provided or made by the installer within the formwork at the desired depth of cover.

Angle iron locators (Octodowel Accessory - sold separately) and 8mm allen key connectors are used to hold the dowel in the desired position.

A bond-breaker is applied on the side of the first pour, which allows the dowel to be extracted for form work removal. The Octodowel is then re-inserted into the formed pocket of the first pour and is then ready for the second pour. Second pour paste fills the Octodowel slot and locks it into place.

Octodowel Accessory needed per Octodowel bordering a "joint" that is shuttered for cast one by means of formwork, removed for cast two for concrete onto said border. Octodowel Accessory can be re-used for next fresh border.

Share